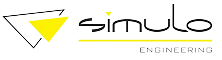

STATIONS FOR SPECIFIC CUSTOMER REQUIREMENTS

Design and construction of stations for automatic management of customer's special processes.

Implementation examples:

- robotic station for laser welding of stainless shower heads. It integrates fiber laser generator, anthropomorphic robot with interpolated seventh axis, automatic part centering and pressing system;

- station for automatic fabrication of flexible control cables with die-cast ends. Integrates system for unwinding, tensioning, pressing and cutting to length (variable length) of steel cable; double anthropomorphic robot; zamak die casting machine; automatic sprue removal, deburring, unloading and scrap management system;

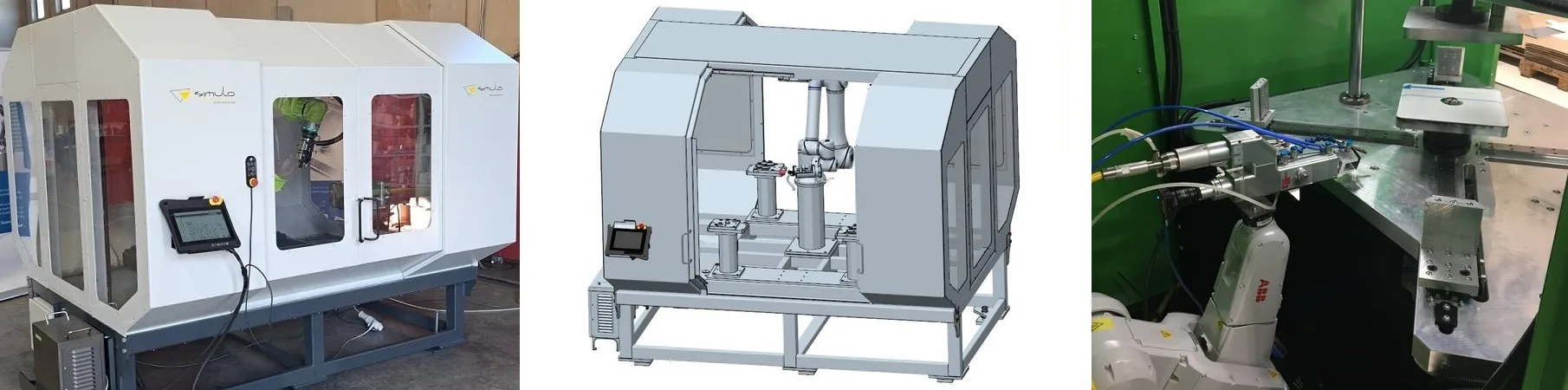

- robotic station for deburring castings. Integrates collaborative robot with load cell for real-time control of pressure exerted on workpiece by grinding tool.